Editorial Note:

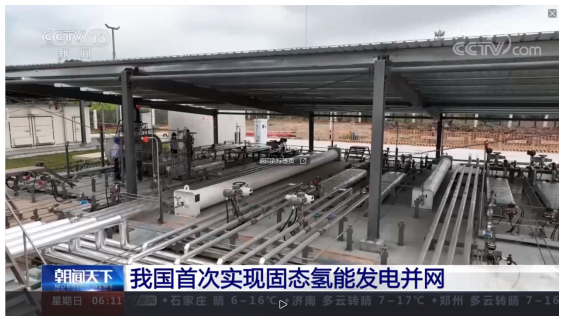

Recently, the team of Profs. Chen Lixin and Xiao Xuezhang from the School of Materials Science and Engineering, and the Hydrogen Energy Research Institute of Zhejiang University cooperated with the team of Profs. Jiang Lijun and Li Zhinian from the China GRINM, published their research work “Machine Learning Enabled Customization of Performance-oriented Hydrogen Storage Materials for Fuel Cell Systems” in the international journal of Energy Storage Materials. Zhou Panpan, the doctoral candidate at Zhejiang University, is the first author of the paper. This research performed implicit/explicit features-based machine learning on the key microstructures/hydrogen storage properties of single C14-Laves type HSAs for the first time. By applying the optimized machine learning model to the alloy composition design for PEMFC hydrogen feeding system, the active performance scanning/prediction and subsequent alloy composition screening of specific parameters are successfully realized. The series of Ti-(Zr)-Mn-Cr-VFe alloys customized by the above advanced strategies show superior comprehensive properties and competitive cost advantages compared with the best materials reported under the same pressure and temperature conditions. Based on the high-performance hydrogen storage materials developed by the joint teams, the developed fast-response low pressure high-density solid state hydrogen storage device was successfully applied to Guangzhou Nansha electric-hydrogen smart energy station, helping China to realize the first time to connect solid state hydrogen power generation to the grid.

Paper link:https://doi.org/10.1016/j.ensm.2023.102964

Hydrogen energy, as a clean, efficient, renewable secondary energy with rich application scenarios, has great potential for application in the fields of transport, renewable energy storage and distributed energy supply across the quarter, which will provide crucial support for the realization of the goal of "dual-carbon". However, how to achieve safe, efficient, and cost-effective hydrogen storage and transportation technology is the core to hydrogen promotion. Compared with high-pressure gaseous hydrogen storage and low-temperature liquid hydrogen storage, low-pressure room-temperature solid-state hydrogen storage is highly favored since its high volumetric hydrogen storage density and the flexibility of performance adjustment. Up to date, metal hydrides with different crystal configurations have been extensively investigated. Among them, single-phase C14-type Laves alloys are widely used in solid-state hydrogen storage devices. In previous works, composition and performance optimization are essentially accomplished through time-consuming and costly trial-and-error means, whereas machine learning-based strategy to design Laves phase-based composition and related properties has rarely been reported, which will be an inimitable direction for further research on hydrogen storage materials.

Recently, the team of Profs. Chen Lixin and Xiao Xuezhang from the School of Materials Science and Engineering, and the Hydrogen Energy Research Institute of Zhejiang University cooperated with the team of Profs. Jiang Lijun and Li Zhinian from the China GRINM, published their research work “Machine Learning Enabled Customization of Performance-oriented Hydrogen Storage Materials for Fuel Cell Systems” in TOP international journal of Energy Storage Materials. Zhou Panpan, the doctoral candidate at Zhejiang University, is the first author of the paper.

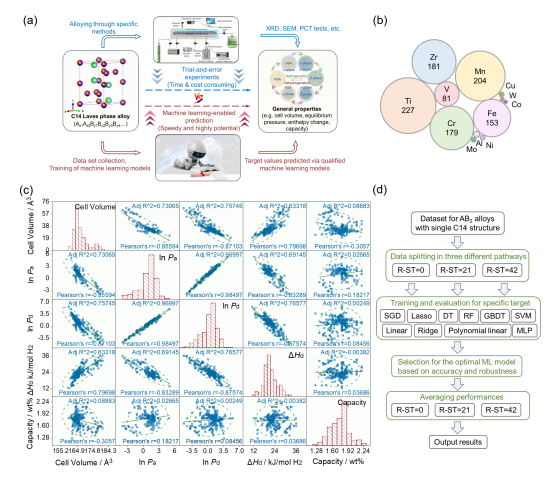

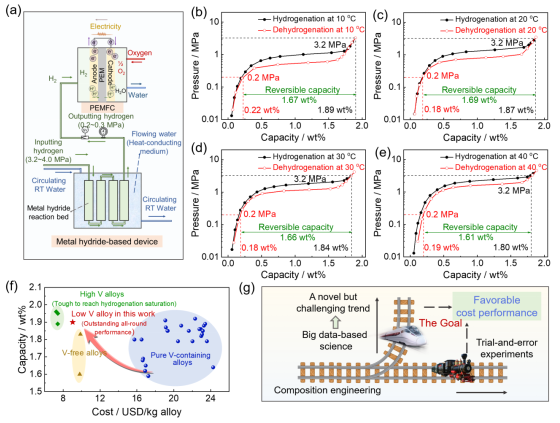

In this work, implicit/explicit features-based machine learning on the key microstructures/hydrogen storage properties of single C14-Laves type HSAs were performed for the first time. Specifically, the SVM model provides a sound description of V and Peq, while the GBDT model has a better representation as to ΔHd and capacity. Among the trained targets, hydrogen storage capacity is the only property indicator that the higher the better, while other indicators will be adjusted according to the requirements of specific applications. On account of the optimal ML model for capacity is the tree-based GBDT, the analysis on feature importance was subsequently conducted, and found that MeanIonicChar value/Fe content are the most pivotal capacity-affecting factors to facilitate capacity estimation and composition formulation of high-capacity alloys.

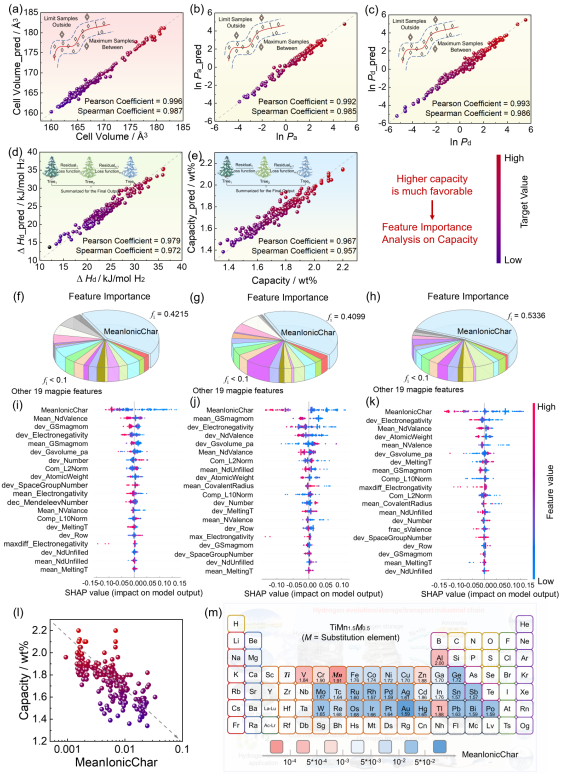

Subsequently, ML-based proactive properties scanning and composition selection were performed for the distributed PEMFC hydrogen feeding system. To address the ML-unavailable potential mechanism, DFT calculations were further introduced, and an intrinsic link between atomic occupancy randomness and sloping PCT plateau was revealed. Generally, the measured hydrogen storage properties exhibit satisfactory accuracy and a validation relationship with the ML-based predicted values. Based on the advanced paradigms above, Ti-(Zr)-Mn-Cr-VFe alloy with superior all-round properties (1.90 wt%, 127.30 kg H2/m3 in saturation) and cost-effectiveness (9.03 $/kg alloy) was successfully customized for application. Based on the high-performance hydrogen storage materials developed by the joint teams, the developed fast-response low pressure high-density solid state hydrogen storage device was successfully applied to Guangzhou Nansha electric hydrogen smart energy station, helping China to realize the first time to connect solid state hydrogen power generation to the grid. The ML-based design framework and associated theoretical analyses here provide a more efficient avenue to the customization of HSMs with superior all-around properties.

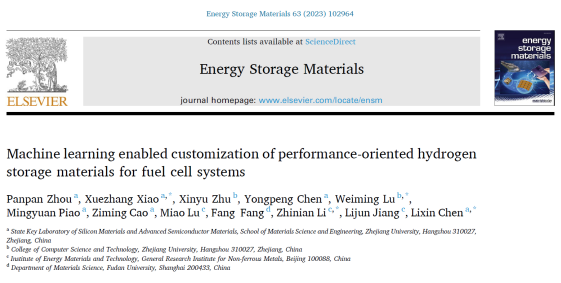

Figure 1. (a) Comparisons between typical trial-and-error experiments and machine learning-enabled composition engineering; (b) Elements prevalence in the dataset; (c) Scatter matrix of the key targets; (d) Overall machine learning process in this work.

Figure 2. Averaging performance of Magpie features-based optimal ML model with different dataset splitting pathways on (a) cell volume, (b) ln Pa, (c) ln Pd, (d) ΔHd and (e) capacity; (f-h) Feature importance and (i-k) feature-related SHAP value for different dataset splitting pathways when training for capacity (Notes: R-ST = 0: (f), (i); R-ST = 21:(g), (j); R-ST = 42: (h), (k)); (l) Relationship between the capacity and MeanIonicChar; (m) Determined MeanIonicChar when part of Mn at B-side of TiMn2 is substituted by other possible substitution elements if all obtain alloys possess a single C14 Laves structure.

Figure 3. (a) Qualitative comparisons of machine learning performance based on different features; (b) Schematic diagram of metal-hydride based distributed PEMFC hydrogen feeding system; Predicted (c) In Pa, (d) ln Pd and (e) capacity for Ti0.9Zr0.12MnxCry(VFe)2-x-y (0≤x, y≤2, 0≤x+y≤2) with the optimal ML models; (f) Schematic diagram of the alloying and properties measurements processes; (g) XRD patterns of selected Ti-(Zr)-Mn-Cr-(VFe) based alloys; (h) crystallographic structure of multi-components C14 Laves phase; (i) SEM image and corresponding EDS mappings of Ti0.9Zr0.12Mn1.2Cr0.55(VFe)0.25.

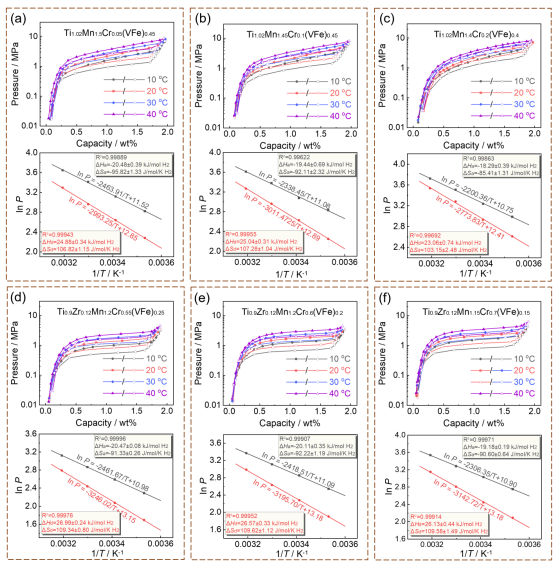

Figure 4. PCT curves and de-/hydrogenation Van’t Hoff curves of selected alloys.

Figure 5. (a) Schematic diagram of distributed PEMFC hydrogen feeding system; (b-e) De-/hydrogenation properties of Ti0.9Zr0.12Mn1.2Cr0.55(VFe)0.25 at different working conditions; (f) Capacity and cost comparison of reported alloys at the equivalent temperature and pressure level (1~3 MPa at 20 oC); (g) Perspective for composition engineering for future works.

Figure 6. The developed fast-response low pressure high-density solid state hydrogen storage device was successfully applied to Guangzhou Nansha electric hydrogen smart energy station.