Corresponding authors: Feng-Shou Xiao, fsxiao@zju.edu.cn; Liang Wang, liangwang@zju.edu.cn; Xiaoming Cao, xmcao@ecust.edu.cn; Jiabi Ma, majiabi@bit.edu.cn

Abstract

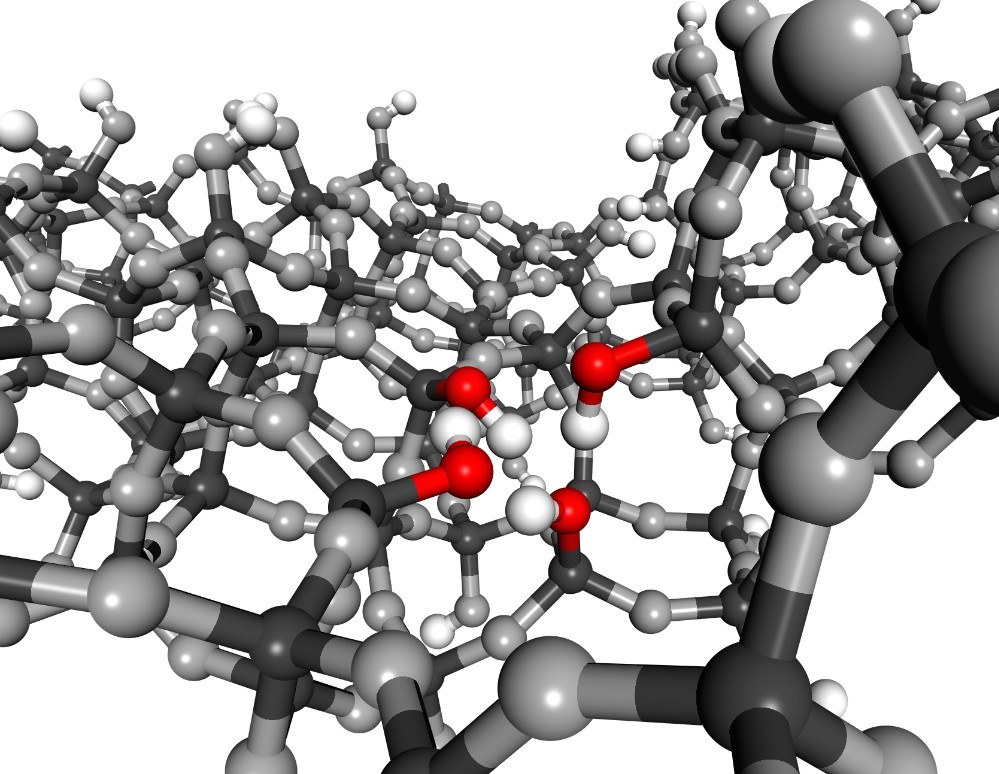

Copper nanoparticle-based catalysts have been extensively applied in industry, but the nanoparticles tend to sinter into larger ones in the chemical atmospheres, which is detrimental to catalyst performance. Herein we used dealuminated Beta zeolite to support Cu nanoparticles (Cu/Beta-deAl) and showed that these particles become smaller in methanol vapor at 200℃, decreasing from ~5.6 to ~2.4 nanometers, which is opposite to the general sintering phenomenon. A reverse Ostwald ripening process was discovered, where migratable copper sites activated by methanol were trapped by silanol nests, and the copper species in the nests acted as new nucleation sites for forming small nanoparticles. This feature reversed the general sintering channel, resulting in robust catalysts for dimethyl oxalate hydrogenation performed with supported copper nanoparticles in industry.

Citation

L. Liu et al., Dealuminated Beta zeolite reverses Ostwald ripening for durable copper nanoparticle catalysts. Science 0, eadj1962 DOI:10.1126/science.adj1962.

Learn more about this article at https://www.science.org/doi/10.1126/science.adj1962.