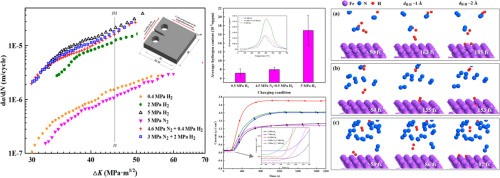

Regarding hydrogen embrittlement (HE) in the mixtures of hydrogen and inert gas, the results were understood mainly based on the partial hydrogen gas pressure. On the other hand, the effect of the total gas pressure has not been fully investigated. In this study, fatigue crack growth rate (FCGR) tests were conducted in high-purity hydrogen gas at different gas pressures. Also, the FCGR tests were conducted in hydrogen and nitrogen mixtures at different total gas pressures. The hydrogen partial pressure in the mixture was the same as the high-purity hydrogen. This was the first time that acceleration of the FCGR in the mixtures compared to that in the high-purity hydrogen was observed. To elucidate the mechanism of the enhanced HE in the mixtures, hydrogen permeation and hydrogen desorption experiments were carried out. Based on the results of these tests, the acceleration of the FCGR in the mixtures could be interpreted by the fast hydrogen entry rate, which may result in a higher local hydrogen concentration near the crack tip during a limited time. Density functional theory (DFT) calculations were performed to consider the total gas pressure effect on an atomic scale. The thrust force of other gas molecules in the mixtures made the hydrogen molecules enter the potential field of the iron surface sooner, advancing the dissociation of the hydrogen. This will increase the surface concentration of the hydrogen atoms.

Citation

Juan Shang, Zhengli Hua, Baihui Xing, Haotian Wei, Jinyang Zheng, Enhanced hydrogen embrittlement of steel by the premature hydrogen dissociation with the increasing inert gas pressure in hydrogen-containing mixtures, Acta Materialia, Volume 259, 2023, 119279, ISSN 1359-6454,https://doi.org/10.1016/j.actamat.2023.119279.

Learn more about this article at https://doi.org/10.1016/j.actamat.2023.119279

(https://www.sciencedirect.com/science/article/pii/S1359645423006092).